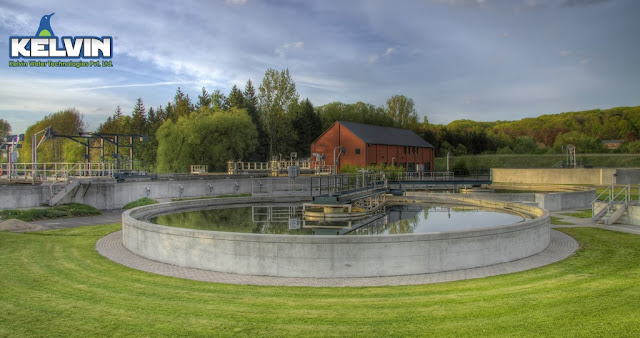

Zero Liquid Discharge Plant Manufacturers in India

The ZLD plant uses progressive technical water management that restricts the amount of water that is discharged at the end of manufacturing procedures. It is able to manage different kinds of contaminants and is able to recover 90% of liquid waste for reuse. The byproducts such as salt are processed a solidified form of waste is disposed of. Components of ZLD plant The zero liquid discharge plant comprises of parts including a reactor that helps to trigger out roughness, metal, and silica. Chemical feed helps to coagulate hard metals and dispersed particles; it also features a screening press to concentrate non-primary solidified effluent after the preprocessing, further, the finer screening helps to eliminate the remaining particles and the risk of corrosion. The vaporizer eliminates excess water content; the crystallizer further provides a solidified form of waste that can be expelled. Advantages of the ZLD plant There are plenty of benefits when the zero liquid discharge...