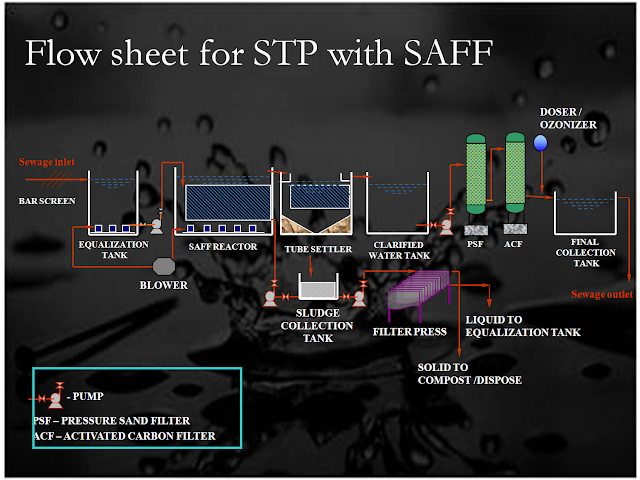

Submerged Aerated Fixed Films (SAFF) Technology

One of the cost-effective methods of waste water treatment and sewage management that is primarily used

in residential and commercial complexes is Submerged Aerobic Fixed Film Reactor

(SAFF). It technology is part of sewage treatment plant (STP). This technology mainly

has three stages that are Primary Settlement, Secondary Treatment and Final

Settlement / Clarification.

Primary Settlement: Here, larger solids get settled at the

bottom of the primary tank and are removed periodically as sludge. Other

buoyant material which floats upwards are usually removed by a

scraping/screening method.

Secondary Treatment: Where the biodegradable Organic Matter

is degraded by the biomass on the SAFF media.

Final Settlement / Clarification: Where degraded solids are

settled out of the biologically treated effluent.

Submerged Aerated Fixed Films (SAFF) technology is a

process used to reduce the organic loading of residential and commercial sewage

/ waste water. The process works towards the reduction of Biological Oxygen

Demand (BOD) and a significant quantity of Suspended Solids (SS) which if

otherwise untreated would contaminate river and other water outlets. In simple

words, SAFF process is used to substantially improve effluent discharge

quality.

In the wastewater industry, SAFF Technology is seen as the

simple and cost-effective method of commercial and residential sewage

sanitation/waste water treatment,

particularly for small to medium sized treatment plants where available land is

limited, and where full time operational manning would be uneconomical. A well

designed Submerged Aerated Filter plant has no moving parts within its process

zones, any serviceable items will be positioned to access easily without

disrupting the ongoing treatment.

Advantages

i)

Deep reactors enabling

small space requirements

ii)

No sludge re-circulation is required to maintain MLSS as in the case of

conventional aeration system.

iii)

Can be designed to any size to deal with larger flow and loads.

iv)

Modular design allows

easy installation.

v)

Use of fine bubble

diffused aeration generally reduces the energy requirements as compared to

surface aerators.

vi)

Ability to effectively

treat dilute domestic wastewater.

vii)

Low & stabilized

sludge production eliminating the need for sludge digestion.

viii)

Higher loading of BOD

on the media enables to reduce the aeration tank size. SAFF requires 25-40%

lesser tank volume as compared to activated sludge process.

ix)

SAFF process able to

achieve 95-98% BOD reduction.

x)

High MLSS – Less Space

required for the treatment.

xi)

Less susceptible to

upsets due to flow variations.

xii)

SAFF supports low

sludge generation, low Odour and low visual impact.

xiii)

Maintenance

requirements are simple.

Disadvantages

i)

High reliance on

external energy input.

ii)

Clogging of reactor

due to absence of primary sedimentation.

iii)

Requires skilled

manpower.

iv)

Reliance on

proprietary filter media.

Comments

Post a Comment