Activated sludge Process Technology for Sewage Treatment Plant

Activated sludge is a

process for treating sewage and industrial wastewater using air and a

biological flock composed of bacteria and protozoa. This process is one part of

Sewage water treatment Plant (STP). The process involves introduction of air or

oxygen into a mixture of primarily treated sewage or industrial wastewater

combined with organisms to develop a biological flock which reduces the organic

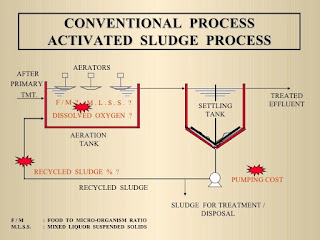

content of the sewage. A Conventional Activated Sludge (CAS) system

commonly includes an aeration tank, which is used for biological degradation,

and a secondary clarifies (sedimentation tank), where the sludge is separated

from the treated wastewater.

This is the most common

and oldest bio-treatment process used to treat municipal and industrial

wastewater. Typically, wastewater after primary treatment i.e. after removal of

suspended impurities, is treated in an activated sludge process based on biological

treatment system comprising of aeration tank followed by secondary clarifies. The first

step of a CAS system is the aeration tank, in this step the wastewater is mixed

with air to activate micro-organisms. While digesting and breaking the

wastewater, the organisms collide with each other, resulting in larger

particles called flocks, and these flocks have a larger capacity to degrade the

biological components of the wastewater. The aeration tank is a completely

mixed or a plug flow bioreactor where specific concentration of biomass,

measured as mixed liquor suspended solids (MLSS) or mixed liquor volatile

suspended solids (MLVSS) is maintained along with dissolved oxygen (DO)

concentration to effect bio-degradation of soluble organic impurities, measured

as biochemical oxygen demand (BOD) or chemical oxygen demand (COD).

The aeration basin is

followed by a secondary clarifies or settling tank. During this step,

micro-organisms with their adsorbed organic materials get settled. Water from

the clarifies is transported to installations for disinfection and final

discharge or to other tertiary treatment units for further purification. The

aerated mixed liquor from the aeration tank overflows by gravity to the

secondary clarifies unit to separate out the biomass and allow clarified,

treated water to the downstream filtration system for finer removal of

suspended solids. The surplus micro-organisms can easily be channeled to any of

the sludge treatment solutions where energy can be recovered from the bio

solids. This additional step closes the energy cycle of the wastewater treatment plant allowing it to run independent of fossil fuel. The separated

biomass is returned to the aeration tank by means of return activated sludge

(RAS) pump. Excess biomass (produced during the bio-degradation process) is

wasted to the sludge handling and de watering facility. Another part of the

micro-organisms is fed back into the aeration tank to keep the load of

micro-organisms at a sufficient level for the biological degrading processes to

continue.

Advantages

·

Good quality effluent

·

Can sustain seasonal variation

·

Self-sustaining system

·

Freedom from flies spread and odor nuisance due to high degree

of treatment

·

Small land area requirement

·

Easily maintained mechanical work

·

Low installation cost (Cost effective)

·

Less land requirement than UASB

Disadvantages

– High energy consumption

– Foaming, particularly in

winter season, may adversely affect the oxygen transfer, and hence performance

– Requires elaborate

sludge digestion /drying/disposal arrangement

– More land requirement

than SBR & MBBR

– Nitrogen and Phosphorous

removal require additional anoxic tank and more internal recirculation

Excellent content on the importance and benefits of Sewage Treatment Plants (STPs)! It's encouraging to see how these systems play a crucial role in treating wastewater, protecting public health, and preserving our environment. By effectively removing contaminants and ensuring clean water discharge, STPs are vital for sustainable urban development. Great job highlighting these critical aspects!"

ReplyDelete"Interested in advanced sewage treatment solutions? Visit MBR Base Sewage Treatment plant In Gujarat to learn about our state-of-the-art MBR-based sewage treatment plants in Gujarat. Contact us today to find the perfect solution for your wastewater management needs!